since 1970 |

KVH-Hartung |

|

|

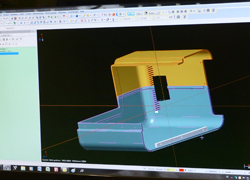

Development and Supervision of Projects You can also benefit from the services of our development and project department. All you have to do is provide us with your project as CAD data (iges or step), a model or a sketch and we will advise you quickly and objectively. Our CAD department will gladly assist you with your design. Here you can find your partners at KVH-Hartung. |

|

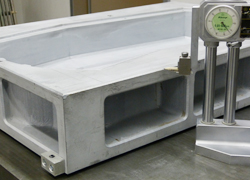

Tool Making |

|

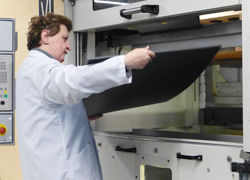

Deep Drawing Universal Illig machines enable tools measuring from180 mm x 220 mm to 2940 mm x 1440 mm and tool heights from 770 mm to be deep drawn. We machine all customary thermoplastics as well as special materials with flame and/or UV protection in a thickness of 0.1 mm to 10 mm. |

|

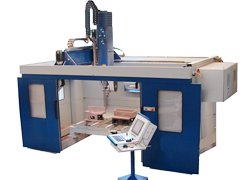

CNC Machining The use of hard plastic jigs during 5-axial CNC machining work together with vacuum enable us to perform absolutely accurate repetitive trimming. This ensures you a precision fit and an easy assembly of your plastic moulded components. |

|

Assembly/Finishing Process |

|

|

Effective date February 2019

|

|